Our Projects

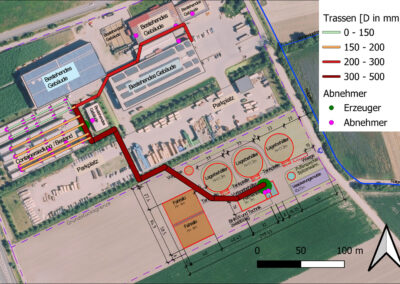

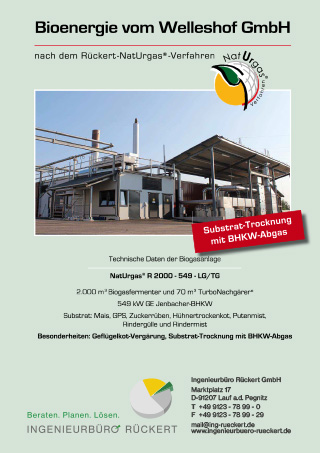

Bioenergy from Welleshof GmbH

- 1 x NatUrgas® with 2,000 m³ digester and turbo secondary digester

- 549 kWel

Input: 30 % poultry manure (turkey and laying hen manure) 52 % maize silage 18 % cattle slurry

Our activities:General planning, project coordination

Turbonach fermenter

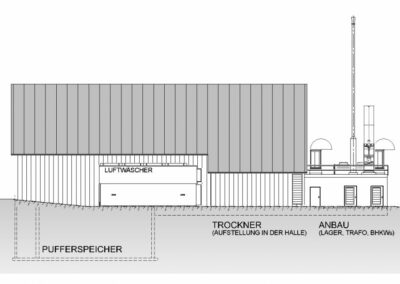

A special feature of the biogas plant is the Turbo secondary fermenter®. This is a high-performance secondary fermenter in which the substrate is fermented again for three days before separation. The TurboDigester® has already proven itself in over 35 Czech Rückert-NatUrgas® plants.

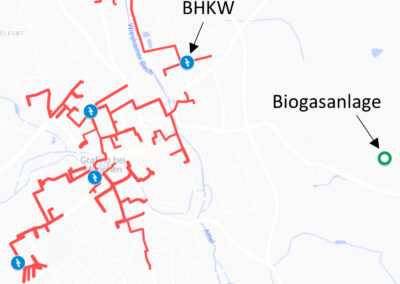

Heat utilisation

The heat energy required for drying is taken directly from the exhaust gas of the CHP unit. On the one hand, this makes the exhaust gas heat exchanger superfluous – the annual cleaning work is a thing of the past – and on the other hand, a larger proportion of thermal energy is available for the drying process.

Here you can find our profile as PDF

Operator quote

“The well thought-out concept allows me to continue sleeping peacefully at night after almost ten years of operation.”

“When it comes to extensions or changes, Ingenieurbüro Rückert is my first choice.”